Service Hotline

+86 13711845437

Manager Zhang

Product Details

Details

Applicable industries

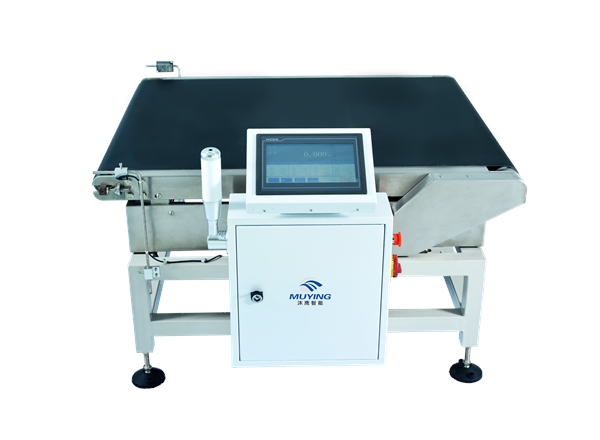

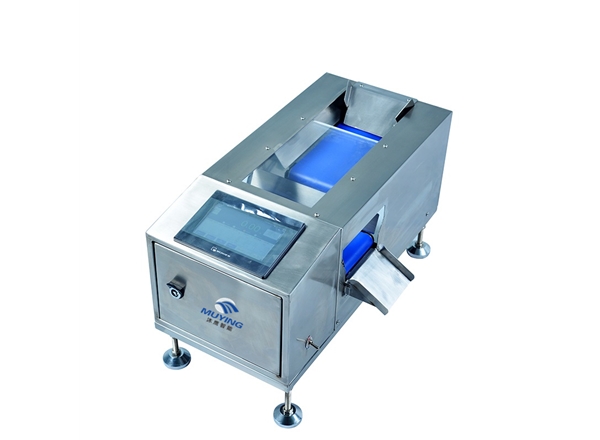

· LMS-A series metal separators can be used to detect metal foreign bodies in raw materials in the chemical industry, plastics and other industries, such as iron, copper, stainless steel, aluminum, etc. culling.

Product Features

1. Adopt German technology, stable performance, can separate magnetic and non-magnetic metals (such as iron, copper, aluminum, stainless steel, etc.)

2. High detection accuracy, metal particles or wires as small as 0.2mm can also be detected.

3. All 304 stainless steel structure to meet the hygienic requirements of the food and pharmaceutical industries

4. Fully enclosed channel, in line with the dust-proof requirements of food and pharmaceutical industries

5. Good detection accuracy, can automatically separate and remove metals

6. Meet the requirements of IFS and HACCP certification

7. Protect production equipment and improve the utilization rate of raw materials

Technical Data Sheet

|

Specification |

25# |

35# |

50# |

65# |

80# |

100# |

120# |

|

Detection channel diameter |

25mm |

35mm |

50mm |

65mm |

80mm |

100mm |

120mm |

|

Sensitivity FE |

0.3mm |

0.4mm |

0.5mm |

0.6mm |

0.7mm |

1.0mm |

1.2mm |

|

Sensitivity SUS |

0.6mm |

0.7mm |

0.8mm |

0.9mm |

1.0mm |

1.5mm |

2.0mm |

|

maximum production |

200Kg/h |

300Kg/h |

700Kg/h |

1000Kg/h |

1200Kg/h |

1500Kg/h |

1800Kg/h |

|

Host weight |

30kg |

30kg |

30kg |

30kg |

30kg |

40kg |

40kg |

|

suitable material |

Granules, powders, flakes |

||||||

* Maximum production capacity: The actual flow is related to the density, fluidity, speed and other factors of the material. Usually the conversion of the processing capacity: the nominal processing capacity of the equipment * bulk density * flow coefficient 0.5-0.7, that is, about kilograms per hour

* Sensitivity: The above data is the maximum detection capability that the device can achieve without any influence. In actual use, it will change due to factors such as the use environment and the product to be tested. The actual test on site shall prevail.

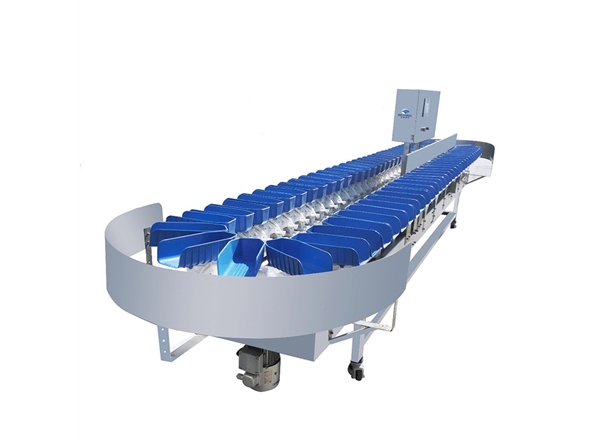

Related products

More>>-

Factors influencing the detection effect of metal detector

Impact of product composition: metal detector mainly detects metal according to the conductivity of the article. Therefo...

Related News

More>>- Sensitivity setting and precautio... 2022-08-16

- Introduction and parameters of me... 2022-08-16

- Precautions for use of needle det... 2022-08-14

- Daily maintenance of metal detectors 2022-08-10

- Metal detector menu key function ... 2022-08-09

- Metal detector installation preca... 2022-08-08

- Overview of Muying LMD Metal Dete... 2022-08-07

- What are the characteristics of m... 2021-10-19